Do you know the best way to find a perfect lotion pump manufacturer in all this confusion and plethora of manufacturers?

Lotion Pumps 101: the Ultimate Guide to Lotion Pumps

There has been a drastic increase in the number of industries worldwide due to industrialization and technological advancement. Do you know the best way to find a perfect lotion pump manufacturer in all this confusion and plethora of manufacturers?

It is overwhelming to most investments to get a 100% reliable lotion pump supplier in these times. It is more overwhelming to find someone reliable. Various fake goods in the market can have their way into your business, making you lose clients. Also, most brands have no perfect knowledge of the lotion pumps they should choose. You may end up selecting a product you do not need. It will mess up your budget and revenue as a company.

It would be best to have a reference guide to help you choose the best manufacturer. Right products translate to excellent customer service and experience. You can also avoid getting fake materials by getting the services of reliable suppliers. Here is an ultimate guide to help you make the best choice on a lotion pump manufacturer.

What Is Lotion Pumps & What’s Inside

Firstly, it would be best to know what lotion pumps are and what their constituents are. Here is a breakdown to help you understand a lotion pump fully.

What is a Lotion Pump?

A lotion pump is a popular dispensing method for thick liquid in the beauty industry. There are several lotion pumps in the market ranging from different sizes to colors and performance. They are very convenient and help you enhance your productivity when used correctly.

What’s Inside the Pump?

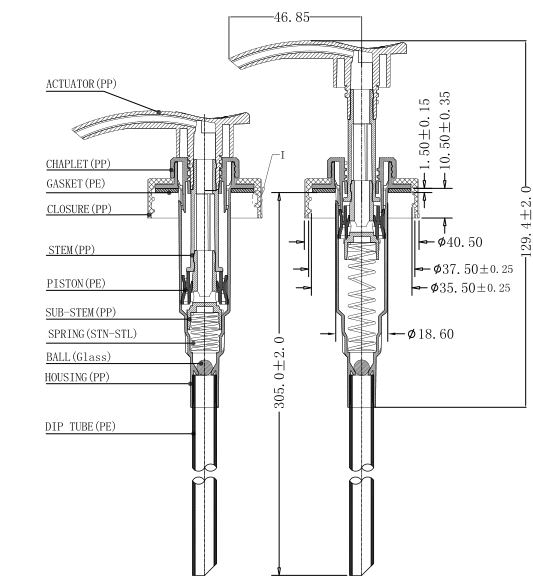

For it to service as it does, it has various components. An overview of these components can help you understand the work of this remarkable machine. From your hand, you can ensure you get the job done within a few minutes effectively and conveniently. Here, look at what is inside a lotion pump as done by crash course1 to help you understand a lotion pump’s work.

1. Actuator

It refers to the pump’s head where you need to press down when you need to work with the lotion pump and make it dispense the product in it. Lotion pumps are made from PP plastics and have no specific design. It can take any shape or size regarding what the manufacturer feels comfortable with. Some are also customized to make them easier to use for a particular group of people, such as PWD.

The device also has an up-lock and down lock. The locks help to prevent any event of accidental pressure on the pump’s head. The actuator is the first physical appearance of the pump that gives them varied looks.

2. Closure

It helps to fasten the bottle and the entire assembly at the neck of the pump. Manufacturers use a common destination to make the closure, such as 28-410 or 33-400. The closure is also made of PP plastic. It comes in different sizes, dictated by the way the lotion pump looks. Most will have a rib side with a smooth side surface.

The closure is made beautiful by installing a metal casing on it. It makes it elegant with a shiny look to impress buyers.

3. Housing

It is the assembly housing of the product. The housing carries all the components putting them in place and holding them ready to work. It is also used as a transfer chamber for the liquid product and links the dip tube to the pump head, then to the user’s hand.

It is also made using PP plastic. The design of the housing differs from one pump to another. Manufacturers can choose their type of housing and create a custom choice easily. It would be best not to pair this type of pump with glass pumps since they have thicker walls with a narrow bottle opening. It may not fit the housing that you need to put it in.

4. Interior components

The interior components include the stem, piston, spring, and ball located in the pump’s internal section. They have no common type since they all depend on the design of the pump. Some pumps have more interior components to help in making them function better and efficiently. These components help in the flow of product in the housing, while some aids can separate the metal spring from the path followed by the product during operation.

The product must not come into contact with any metal. It prevents any compatibility challenges that may arise on the metal spring.

5. Dip tube

It refers to a long tube made from PP plastic. It runs through the lotion pump from top to bottom. It also enables the pairing of your pump with others seamlessly. The length differs with the type of pump with which you are pairing. You must cut the dip tube appropriately to make it easier to work and maximize your productivity. It is also essential to prevent any clogging that may occur during the liquid product’s dispensation.

How Does a Lotion Pump Work?

Here you will understand the working principle of a lotion pump. The guide will help you understand how the components work in unison.

First press

The first press refers to when you put the pressure on the actuator for the first time. The press will cause several activities inside the pump. The STEM drive and the SUB-STEM in unison will put pressure on the spring. The spring is compressed, releasing pressure on the piston outer wall, which causes friction on the inner cavity wall. As this happens, the friction will make the piston to create a hole on the SUB-STEM. The discharge hole will dispense the liquid up when the piston slipping goes down, moving through the air inside the housing.

Press several times

If you continue pressing on the actuator, it results from the discharging of all the air within the actuator. All the air in the housing is discharged through the discharge hole on the SUB-STEM.

Lead the liquid into the pump housing

It would help if you pressed the actuator by hand following the column, vice column, piston, and joint compression will let the air out. The piston will be moving down as a result of friction. The discharge hole is closed, and a vacuum state is formed inside the housing. Here, the glass ball gets sucked up, leading to more liquid suction into the storage cavity.

Reserve the liquid

It is simple to store the liquid. Press the actuator severally. The liquid is stored through several suctions by many presses on the head of the pump. Press until the liquid is entirely stored inside the pump effectively.

Discharge

The stored liquid should reach its capacity by filling the liquid cavity. When it is full, the liquid will be ejected from the nozzle when you start another pressing session.

Can Lotion Pumps Be Recycled?

Can lotion pumps be recycled? It may not be easy to recycle lotion pumps due to the composite materials used to make them. Whenever a product is made with several other materials, it results in a composite packaging that may not be recyclable.

Some manufacturers use composite materials making the recycling process overwhelming or even impossible. Lotion pumps have several composite materials such as PP plastic, metal springs, and a glass ball. You have to remove these parts apart to get some recyclable and some which are not. You can recycle plastic parts with other plastic items.

However, it can be challenging to get the correct combination for recycling. You can choose the best option to avoid products that have no way to recycle after use. It is best to have eco-friendly packages. Select among the best PET bottles and the available 90% lotion pumps to avoid the recycling hassle.

It would also help to continue refilling the bottles instead of buying new ones. Reusing is one of the best forms to conserve the environment. The pumps are practical to use for an extended time. Avoid repeat buying by using your pump effectively and carefully to avoid breakage.

Wrap Up

It is overwhelming to get the best lotion pump supplier. If you are new to the business, it gets more complicated with the numerous options you choose. Most businesses end up selecting products they don’t need or those that don’t satisfy their clients. Before you make your selection, do your research, and know the type of product you want to order. You can also request samples and see how it works before you make any purchase.

It is best to have lotion pumps since they are advantageous packaging options for most brands. Any business in the beauty industry, such as skincare brands, cleaning brands, hand sanitizer brands, and cosmetic brands, requires lotion pumps to boost productivity. Selecting the best product helps you to satisfy your clients. With this fantastic product, you will give your customer the best experience, and they will be loyal to your brand.

Have you decided to get the best lotion pump solution for your company? We are the best suppliers in town for bottle wholesalers, B2B firms, and packaging brands. At PumpSpace, we provide the best lotion pump solution to our customers. We offer free advice and consultation services to help you make the perfect choice for your business. We ensure your brand gets the best lotion pumps by customizing the products with your brand type. We have numerous samples to show you and help you choose the most appropriate sample. We have direct links with reliable manufacturers and suppliers to avoid the struggle of looking for them.

Call us now with your specifications and get cutting edge services at unbeatable prices.

Welcome to the

Your go-to destination for packaging tips, the newest packaging trends, and inspiration.

We’re the pro supplier and manufacturer of all kinds of bottles and sprayers, feel free to talk about your requirements.

Follow us on: