Lotion pump products are widely used in the packaging of daily chemicals, cosmetics and medical supplies such as beauty, hairdressing and washing products.

A Guide to History of Lotion Dispensers

A pump is a mechanical device that releases the contents in a predetermined form through the principle of generating a vacuum by pressing and has a sealing performance.

After decades of development, pumps have penetrated into every aspect of daily life. Moreover, the functions, appearance, and practicability have been greatly improved.

The following is a brief introduction to the development history, working principles, and inspection standards of various pumps.

Let’s dive right in!

The History of Dispensing Pumps

There are historical records that can be found in China, 500 years ago, in the 14th year of the Ming Dynasty (AD 1449), this type of dispenser was commonly used, and it was called “water dragon”.

“Water dragon” is the common name for fire extinguishers in the old days: it consists of a wooden barrel about 0.8 meters high, about 0.8 meters wide and about 1 meter long, and several auxiliary buckets, equipped with water hoses, spray gun heads and other facilities.

A well-shaped wooden pad is installed at the bottom of the bucket to facilitate the stable placement of the water dragon. Two pumps made of copper are placed side by side in a large wooden barrel.

There is a piston in the pump that can be moved up and down. There are water inlet and water outlet valves inside. The piston is connected with the upper lever. Press the lever and water can be sprayed out. The two walls on the left and right of the barrel wall are equipped with a movable iron ring handle, which is convenient for two people to lift the water dragon when saving water, and the other two use one hand to assist with the handle to reduce the load of the person carrying the water dragon, speed up the running speed.

The comparison of the development of Chinese and foreign modern history is also reflected in the development of the distributor. Industrialized production and consumer demand have brought about the vigorous development of European and American distributors. The first thing that emerged was the dispensing pumps.

- The concept of aerosol valve originated in 1790 with the introduction of a pressurized carbonated beverage in France.

- In 1837, a person named Perpigna invented an aerosol bottle containing soda water.

- In 1899, inventors Herlbling and Pertsch applied for the first patent for aerosol cans using methyl and ethyl chlorides as propellants.

- In 1930, the French cosmetic giant L’Oreal invented Lotion (lotion). But that is not as convenient as the use of lotion pumps. The most commonly used are lids (Qianqiu lids, butterfly lids, and even aluminum cans). Nowadays, there are still a considerable part of the market in Europe and the United States in large-package shampoos and shower gels. Especially the reasons: one is the traditional use habit, and the other is environmental protection.

- In 1966, an eighth grade student in a junior high school in Quebec, Canada, used a ballpoint pen and a tube to invent our first lotion pump in a science experiment class. At that time, a large hand sanitizer company used this design to develop a lotion pump head that could be mass-produced (and was respected and did not apply for a patent), which is the prototype of the pump head structure we commonly see today.

- In 1996, a European and American company caused a water intake problem due to a design defect of the lotion pump head used in baby products, which constituted a lawsuit. Three companies around the world set out to invent the anti-inflow pump head that has led the trend for decades. The lotion pump head enters a new era.

- In 2013, a domestic manufacturer in China responded to the new demands of the daily chemical giant Unilever’s Unilever market and launched the world’s first lotion pump specifically for e-commerce channels.

History of international development

Aptar — Founded in 1940

Coster — Founded in 1963

WestRock(Calmar) — Founded in 1969, introduced the first generation of Shower Guard pumps in 1997

Albea — Completed the acquisition of Rexam in 2010

History of development in Asia

Japan

Toyo Seikan — Founded in 1917

Yoshino — Founded in 1935, introduced the first generation of waterproof pumps in 1997

Daiwa Can — Founded in 1936, sold the first airless packaging design to Airspray in Holland

Mitani — Founded in 1956

Canyon — Set up factory in Korea, which leaded the popularity of Korean manufacturers

Korea

Apollo — Founded in 1976

Yonwoo — Founded in 1983

Chongwoo — Set up agent in 1992

Darin — Founded in 1993

China

Sunrise — First introduced 3.5ml lotion pumps in 1979

TKK — The agent of many European dispensers since 1976

JM — Founded in 1987

TKPC — Set up its factory since 1992, the inventor of the first generation WaterShield waterproof pumps

ZZ — Founded in 1992

CLC — Founded in 1994

Majesty — Founded in 2001

Working Principle of Lotion Pump

We’ve talked about this at Lotion Pumps 101: the Ultimate Guide to Lotion Pumps, but we’re going to make things clearer and simplier.

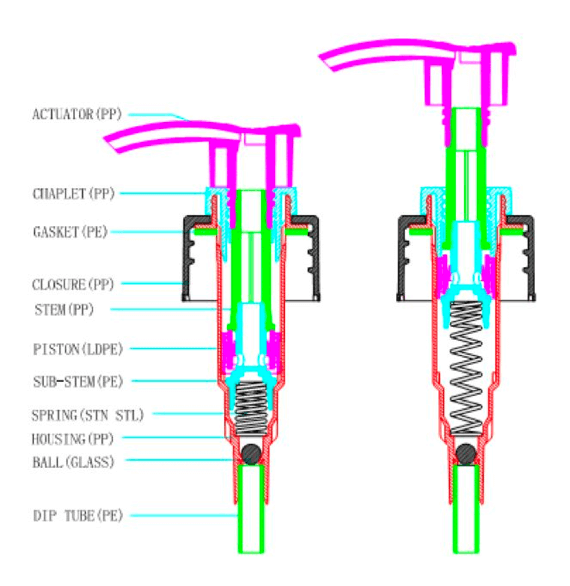

When the actuator is pressed for the first time, the ball valve and the housing are closed, and the air sealed in the body is forced to be discharged from the sub-stem hole through the nozzle;

When the head bounces up, the piston and the auxiliary column are in a sealed state, and continue to rise under the force of the spring to form a sub-vacuum state in the body to generate suction, and the liquid will pass through the dip tube, the ball valve enters the body;

When the head is pressed down again, the ball valve and the body are closed, and the liquid in the body is squeezed, and it will be forced to be discharged from the auxiliary column hole through the head nozzle!

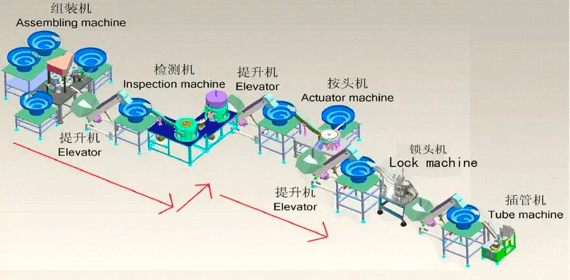

Craftsmanship of Lotion Pumps

Inspection and Quality Control

- Tightness: Fill the bottle with colored water (or customer liquid) according to the product specification, use the corresponding torque according to different calibers to match the pump head with the bottle, press the head in a locked state, place it horizontally, and vacuum test- 0.03~-0.06MPa/5min (different customer requirements are inconsistent). After the test, there is no leakage at the fitting place of the bottle and the screw, the fitting place of the body and the cap, and the pressing head.

- After the press head is matched with the main column, the separation force between the press head and the main column must generally be able to bear the weight of the entire package. General parameters can be qualified as not less than 2Kgf.

- Air pressure times/first spray times. It refers to the total number of times the consumer presses the head since he opened the head until the first time the liquid was discharged. The common standard is 6-10 times.

- Pump output: refers to the volume of the pumped liquid each time the consumer uses the emulsion pump. The tolerance of the usual pump output is about ±10% of the theoretical design value.

- The opening torque between the press head and the lock cover is 3-10Kgf. cm.

- Drop test: match with the corresponding bottle, fill the standard weight of liquid (or water), drop it once vertically from a height of 0.8 to 1.2 meters on the concrete floor, the bottle touches the ground first, and the product is qualified if it is not broken or loose. (Note: This test is only carried out on the product when the material is changed or the formula is changed, and the new mold is first mass-produced).

- Hand feel of the pump: good rebound, no sluggishness, rebound time ≤ 1.5 seconds, fatigue test after pressing ≥ 2000 times, the rebound must be normal.

- The tightness of the straw and the body should be moderate, not too loose (easy to fall off) or too tight (easy to burst the body). General parameters can be qualified as not less than 0.5Kgf (products with different hose specifications need to be re-evaluated).

- The screw thread fits smoothly with the bottle mouth, without slippage, blockage, and crookedness.

The Future of Lotion Pumps

Lotion pump products are widely used in the packaging of daily chemicals, cosmetics and medical supplies such as beauty, hairdressing and washing products.

Its main characteristics are simple structure, stable function, convenient use, environmental protection and beautiful, high quality and low price, wide use, and market potential Huge and high demand.

Since entering the 21st century, China’s daily chemical and packaging industries have faced unprecedented opportunities for development. The packaging industry of daily chemical products is also developing into an emerging industry with continuous technological advancement, increasing value-added and a more impressive scale!

Welcome to the

Your go-to destination for packaging tips, the newest packaging trends, and inspiration.

We’re the pro supplier and manufacturer of all kinds of bottles and sprayers, feel free to talk about your requirements.

Follow us on: